Production Blow Molds

Our ultimate goal is to provide the highest quality production molds and secondary tooling for the blow molding industry. Our design and prototyping processes help ensure your production molds hit the ground running. Every customer and every job is unique. We pride ourselves on understanding each individual customer’s needs and expectations.

Custom Mold Technology to Fit Your Production Needs

At Fidelity Tool & Mold we are always looking for better and more efficient ways to build value for our customers. We developed MPL (Multi Parting Line Technology) which has virtually doubled the output of conventional machines. Development and research continues on many programs that we will launch in the future. Our company is dedicated to continue searching for better and more innovative ways to produce our products.

Capabilities & Applications

No matter the machine platform, make or model, we can design and build molds and trim tooling that meet your needs. We have completed builds for over 75 different machine models and growing—Including the latest state of the art all-electric machines.

Machine Platforms Serviced:

Shuttle Platform Extrusion Blow Molding

Bekum, Battenfeld Fischer, Automa, Technie, B&W, Hayssen

Wheel Machines

Graham, Urola, Consolidated, Willmington

Reciprocating Screw Blow Molding Machines

Uniloy, Davis Standard, Liberty, Rocheleau

Injection Stretch Blow Molds

Injection stretch blow molds

Nissei PF8-4B, Nissei 70DPW

Kautex and Uniloy Milacron… and more!

Engineered to Support High Production Molding

Fidelity’s 6-Points-to-the-Finish Process:

- RFQ presented within 48 hours of request

- Delivery established day of purchase order/authorization

- Specifications reviewed

- Progress reports provided continuously to customer

- Tooling delivered on schedule

- Modifications made and follow-up service provided

One Focus, One Customer at a Time

With more than 25,000 square feet and a full staff of engineers and technicians, Fidelity continues to produce blow mold solutions of exceptional quality that meet the individual needs of each customer. We communicate with customers beyond their expectations. And, we strive to produce innovative tooling that will help customers sustain their business more profitably and efficiently.

Explore Our Production Molding Work

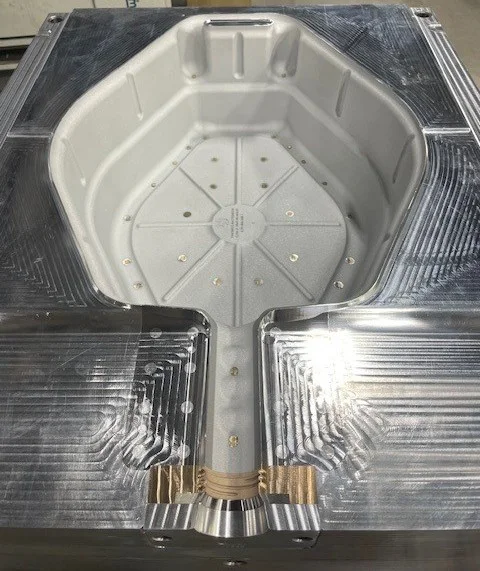

Oil Pan

Ice Pack Quad

Side Mount Trim

Handle and Shoulder Blocks

H155 Quad

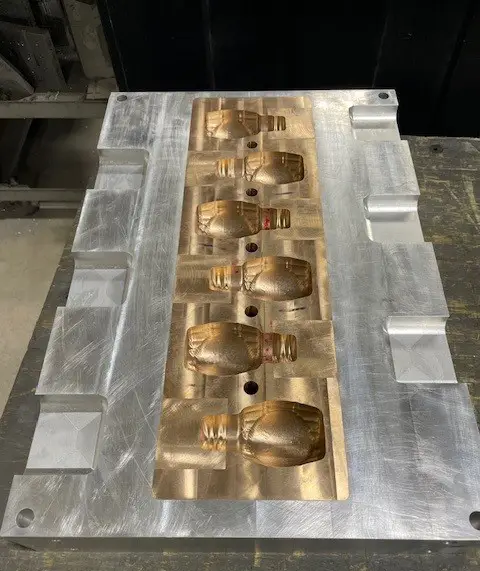

Butter Beer Cavities

Bushing Side Quad

Back Side Cavity Showing Cooling

2 Quads Finished w/Detabbers

Frequently Asked Questions About Our Production Blow Molds

What is the lead time for production molds?

Lead times can vary significantly based on current shop demand and the type of mold. It’s always best to check in 1-2 weeks prior to placing the order, if your quotation is older. As a rule of thumb, smaller shuttle molds can normally be completed in 6-8 weeks. Larger complex molds with trim tooling normally run 10-12 weeks.

How do I request a quotation, and how long does it take to receive?

RFQ’s are accepted over the phone or via email. You will receive a response within 48 hours.

What if I have issues running my new mold?

We warranty our molds and will make adjustments needed to get your product in specification and your mold running efficiently.