Prototypes/Design

At Fidelity Tool and Mold we offer turn key solutions that include product design, SLA/ 3D printing, and rapid prototype molds.

Design Services

Our product designers have extensive experience in 2D and 3D design. We assist customers designing a product that not only meets the functional requirements but is also optimized for manufacturability.

SLA/3D Printed Models

When a model is needed to verify dimensions, shape, or functionality, Fidelity can provide a 3D printed model in typically 3-5 days.

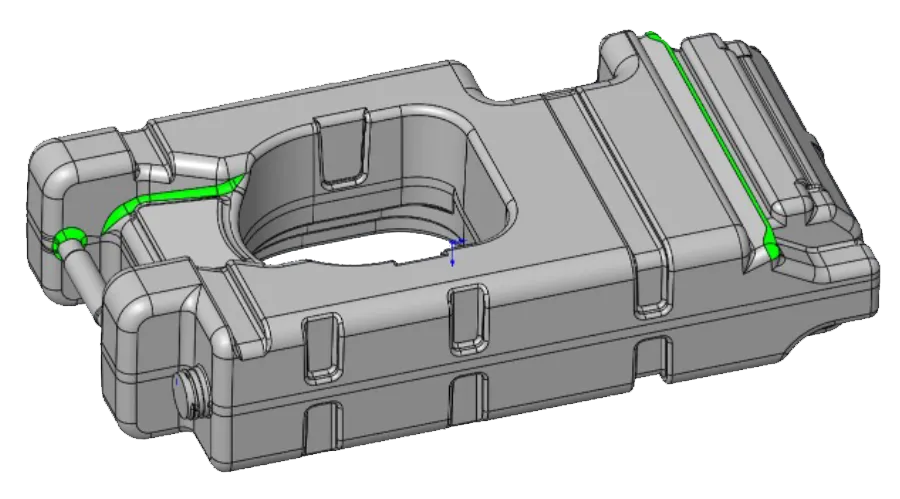

Rapid Prototype Molds

If you are still not sure if you’re ready to commit the design to production tooling, we can build a low cost rapid prototype tool that allows you to validate the design in the same material planned for production. These are single cavity metal molds completed in 2-4 weeks, and are capable for producing a few thousand units.

Explore Our Blow Mold Prototyping Work

Title

Title

Title

Title

Title

Title

Frequently Asked Questions About Our Prototyping Services

Do I need to provide a basic design of the product I have in mind?

NO. You can consult with our product designers about your basic needs and ideas. They will generate initial designs for review. These can be tweaked or revised until your expectations are met.

What are the advantages and limitations of 3D/SLA models?

The 3D printed models can be generated very quickly, and used to verify size, shape and dimensions. They should not be used for evaluating mechanical/chemical properties as they are made with different materials/ processes.

When should a rapid prototype mold be utilized, rather than making several 3D printed models?

When higher unit quantities are needed, in the material that will be used for production units.